Puff Pastry: The Importance of Resting Periods in Their Manufacturing.

Laminated products require precise dough rheology to achieve their layered structure. Dough elasticity, extensibility, and fat distribution are key to texture and volume.

Why are Resting Periods Necessary?

During lamination, repeated sheeting and folding alter dough rheology. Mechanical work increases elasticity while reducing extensibility, making the dough prone to tearing.

This can disrupt dough-fat layering, compromising lift and structure. If steam escapes through holes in the dough layers during baking, volume and flakiness suffer.

Resting periods counteract these effects by allowing the dough to relax. Over time, it becomes less elastic and more extensible, reducing sheeting stress and preserving distinct dough-fat layers, essential for high-quality laminated products.

How Long Should The Dough Rest?

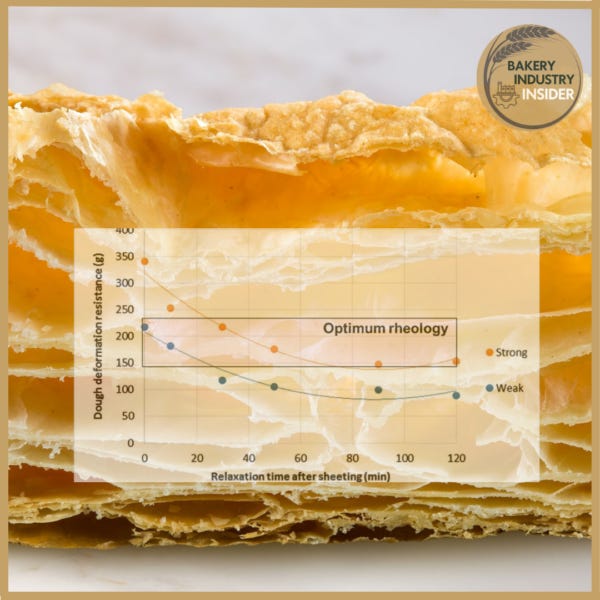

It depends on the flour type:

1. Strong Flour (high protein, elastic gluten)

Requires longer resting periods to reach the ideal rheological state.

The elastic gluten network needs more time for relaxation to ensure smooth sheeting.

Without enough rest, the dough remains tight and prone to tearing.

2. Weak Flour (low protein, less elastic gluten)

Enters the optimum rheological zone faster and requires shorter resting periods but is 𝗹𝗲𝘀𝘀 𝘁𝗼𝗹𝗲𝗿𝗮𝗻𝘁 to process delays.

Over-resting weak flour can cause excessive softening, reducing its ability to hold lamination.

Which Flour is Better for Laminated Products?

It depends on production needs.

For industrial, high-speed processing: Weak flour is preferable as it allows rapid production without extended resting periods. However, it lacks tolerance for unexpected delays.

For artisan or controlled manufacturing: Strong flour is better as it maintains dough integrity, leading to consistent results, well-defined layers, and superior lift.

Source: lnkd.in/dTbC4qkK