Excessive Shrinkage in Puff Pastry

Causes and Prevention

Shrinkage is a common challenge in puff pastry production. While some degree of shrinkage is natural, excessive shrinkage negatively impacts product quality, appearance, and yield.

Mass production of puff pastry tartKey Causes of Excessive Shrinkage:

1. Flour Strength Mismatch

Using flour with higher protein content and robust gluten networks can lead to excessive shrinkage if not managed correctly.

Such flours inherently increase dough elasticity, leading layers to retract during baking.

Adequate resting periods are necessary to ensure dough extensibility and minimize shrinkage.

2. Presence of Oxidants

Oxidants such as ascorbic acid in flour or dough formulations strengthen gluten networks, potentially causing excessive elasticity and shrinkage.

3. Dough pH Imbalance

Acidic conditions, resulting from excessive acid addition, can amplify shrinkage.

Acidification strengthens gluten by tightening protein bonds, which improves lift but also increases dough elasticity and its tendency to contract.

High acid levels can lead to uneven expansion or even collapse in shape-sensitive products, especially when natural flour buffering capacity is exceeded.

4. High Sugar Levels

Excess sugar content can chemically interfere with the dough matrix in several ways:

Sugar is hygroscopic—it binds water in the dough, reducing the amount available for proper gluten development. This leads to a weaker gluten network.

High sugar levels also delay protein hydration, further hindering gluten formation.

During baking, sugar promotes faster browning and crust formation, which can trap steam unevenly and exacerbate shrinkage.

The combination of weaker structure and uneven internal pressure leads to contraction and structural collapse, especially in laminated doughs where precision and balance are key.

5. Excessive Use of Recycled Trimmings

Recycled dough trimmings often contain partially developed or overworked gluten, making their structure inconsistent with freshly mixed dough.

When these trimmings are added during sheeting instead of during mixing, they are not evenly integrated into the dough matrix.

This inconsistency results in localized areas of varied elasticity, causing uneven expansion and higher shrinkage.

Additionally, if reducing agents were used previously, their residual activity in recycled trimmings can overly soften specific regions of the dough, further destabilizing its structure during baking.

6. Insufficient Relaxation

Insufficient relaxation periods during processing stages, particularly after cutting and before baking, lead to increased dough elasticity and shrinkage.

Repeated working of the dough increases its elasticity and reduces extensibility due to gluten tightening.

Without resting, this tension remains, causing the dough to snap back during baking and shrink.

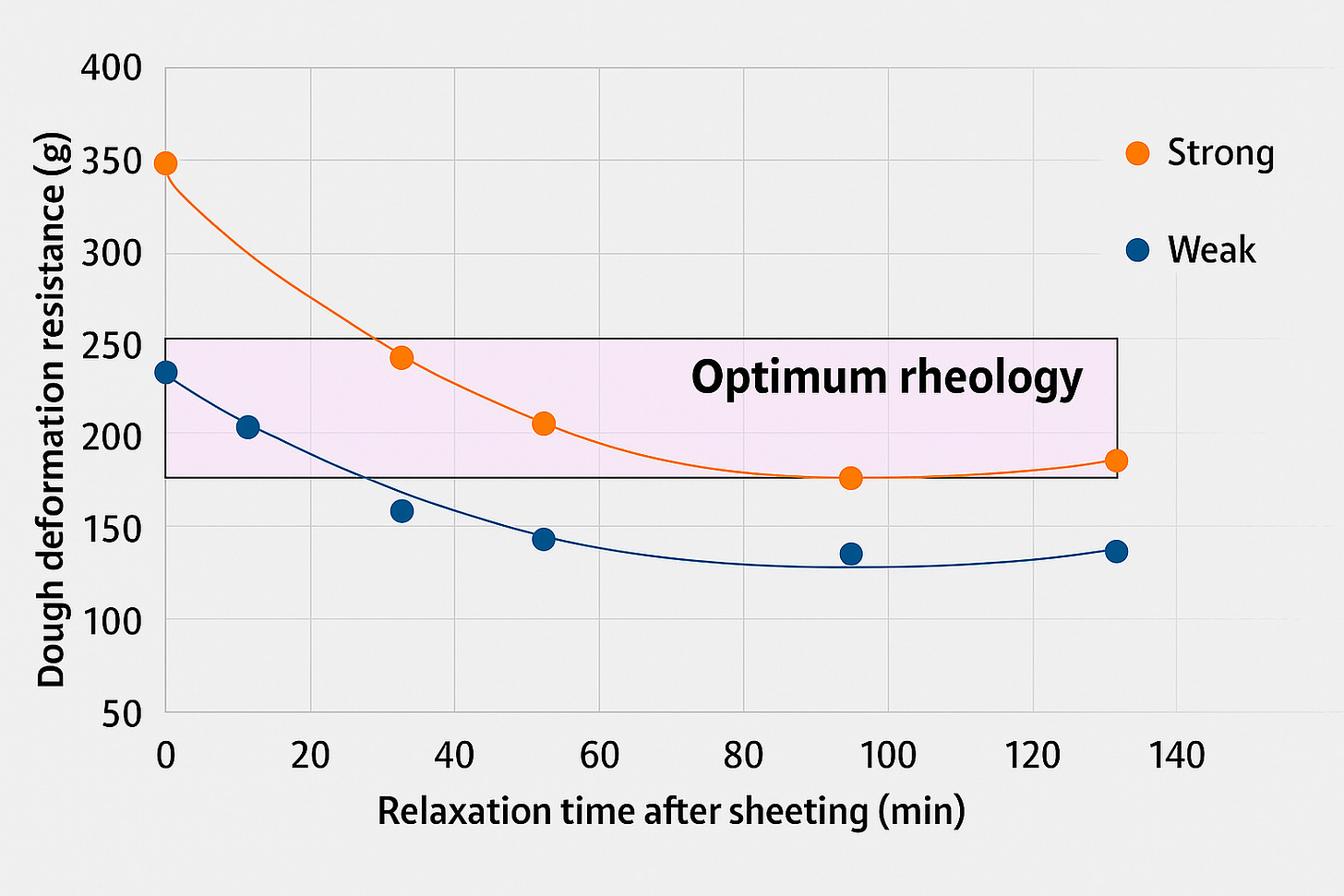

Resting allows enzymatic and biochemical processes to soften the gluten network, especially in strong flours that require longer times to rebalance their rheology.

Proper relaxation preserves the laminating structure and helps achieve uniform lift and shape retention.

Effect of relaxation time on dough deformation resistance with two flours

How to Prevent Excessive Shrinkage:

1. Optimize Flour Selection and Resting Periods

Match flour strength with processing methods.

Allow sufficient relaxation time to reduce elasticity.

Weak flours might require shorter resting times but lack tolerance to processing delays.

2. Control Dough pH

Avoid excessive acidification:

Limit acid addition to levels optimizing lift without increasing shrinkage.

Consider flour buffering capacity when formulating recipes.

3. Balance Recipe Formulation

Carefully manage sugar content and oxidants:

Lower sugar levels to reduce shrinkage.

Minimize or control oxidant usage, particularly ascorbic acid, to avoid excessive gluten strength.

4. Manage Use of Recycled Dough

Incorporate recycled trimmings during initial mixing rather than later sheeting stages to ensure uniform dough properties.

5. Adequate Dough Relaxation

Ensure sufficient dough relaxation at critical processing points:

After mixing, before sheeting.

After laminating, before cutting.

Post-cutting, before oven entry.

6. Caution with Reducing Agents

Reducing agents like sodium metabisulphite or L-cysteine hydrochloride can mitigate shrinkage by weakening gluten. However:

Use sparingly due to potential adverse effects on dough structure, especially in recycled dough.

Prioritize other shrinkage-prevention methods before introducing reducing agents.

💬 Thanks for reading! If you found this helpful or have your own experiences to share, drop a comment below—we’d love to hear from you!

Source: https://lnkd.in/dj6xqqGh