Dark Streaks and Patches with a Coarser Cell Structure in Bread Crumbs: Diagnosing and Solving

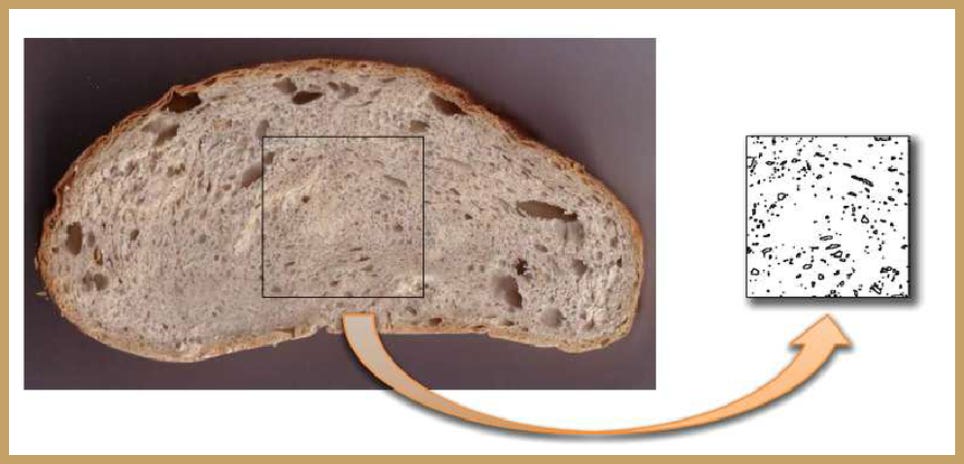

A common issue with crumb appearance is the presence of dark streaks or patches with coarser cell structures and firmer textures.

These inconsistencies can impact the product’s aesthetic and perceived quality.

Understanding the Issue

Dark patches in bread crumbs arise from variations in cell structure, primarily due to the disruption of bubble stability in the dough. Key observations include:

Larger crumb cells with darker shadows caused by ruptured or coalesced gas bubbles.

Thicker cell walls contribute to darker crumb coloration.

These anomalies often stem from processing stages that stress the dough’s gluten network, such as mixing, dividing, and molding.

Key Causes of Dark Patches

Mixing Inconsistences:

Insufficient energy or mixing time leads to underdeveloped dough.

Gas bubbles remain unstable, compromising crumb structure.

Flour Properties: Weak flour, with lower protein content, produces a weaker gluten network that lacks the elasticity and strength required.

Dough Improvers: Inadequate use of hard fats, emulsifiers, or other improvers in no-time doughs.

Hydration and Temperature:

Low water content results in tight doughs, making them prone to damage.

Cold doughs yield stiff, underdeveloped structures.

Proofing Issues: Insufficient first proofing fails to relax the dough adequately.

Molding Settings: Excessive pressure during molding damages the gluten network, leading to coalescence of bubbles and dark patches.

Contamination Risks: Inclusion of old, fermented dough or improper handling between molding stages can introduce inconsistencies.

Practical Solutions

Monitor dough development to achieve optimal gluten structure during mixing.

Use flour with a protein content of 11-13%, which provides adequate strength.

Include fats with a high melting point, emulsifiers, or specific improvers for no-time doughs to enhance bubble stability.

Adjust Dough Hydration and Temperature: Aim for a well-hydrated, softer dough and maintain its temperature within recommended ranges to prevent stiffness.

Allow sufficient time for the first proof to relax the dough, monitoring proofing conditions to prevent underdevelopment.

Adjust molding equipment settings to minimize excessive pressure and avoid damage to the dough.

Source: https://lnkd.in/dH57zfdT